September 18, 2024

New 3D Metal Printing Service

Metal 3D printing is revolutionizing manufacturing by enabling the creation of complex, precise and resistant parts in a more efficient way. At Godiz, we have incorporated this service to offer customized solutions that optimize both design and production. This technology reduces lead times, material waste and allows us to manufacture components with advanced geometries, driving innovation in key industrial sectors. Our commitment is to offer our customers a competitive advantage with this advanced manufacturing technique.

What is metal 3D printing?

Metal 3D printing is an additive manufacturing process that allows parts to be created by adding layer by layer of metallic material, such as steel, titanium or aluminum. Unlike traditional machining methods, which involve sculpting or cutting the material, 3D printing builds directly from a digital model. This makes it possible to produce complex and detailed geometries that would be impossible or too costly to produce otherwise.

One of its main advantages is the ability to minimize material waste, as only the metal needed for each part is used, making it a sustainable option. In addition, this process significantly reduces production times, especially in the creation of prototypes or customized parts, which makes it very attractive for industries such as automotive, aeronautics and engineering.

The impact of metal 3D printing is evident in sectors where strength and precision are crucial, enabling the manufacture of components that are both strong and lightweight. This technology provides the flexibility to adapt designs according to project needs, allowing manufacturers to innovate and experiment without the limitations imposed by conventional manufacturing methods.

Metal 3D printing applications

Metal 3D printing has applications in a wide range of industrial sectors, due to its ability to manufacture customized and highly resistant parts. In the automotive industry, it is used to create lightweight components that improve performance and reduce production costs. In the aerospace sector, it enables complex parts to be manufactured more quickly and accurately, optimizing weight and durability. And in the engineering field, it is ideal for functional prototypes and one-off custom parts.

Its flexibility makes it ideal for medicine, where customized implants are created, and for the energy industry, manufacturing durable parts for extreme environments. With metal 3D printing, companies can innovate, reduce lead times and improve efficiency at every stage of the production process.

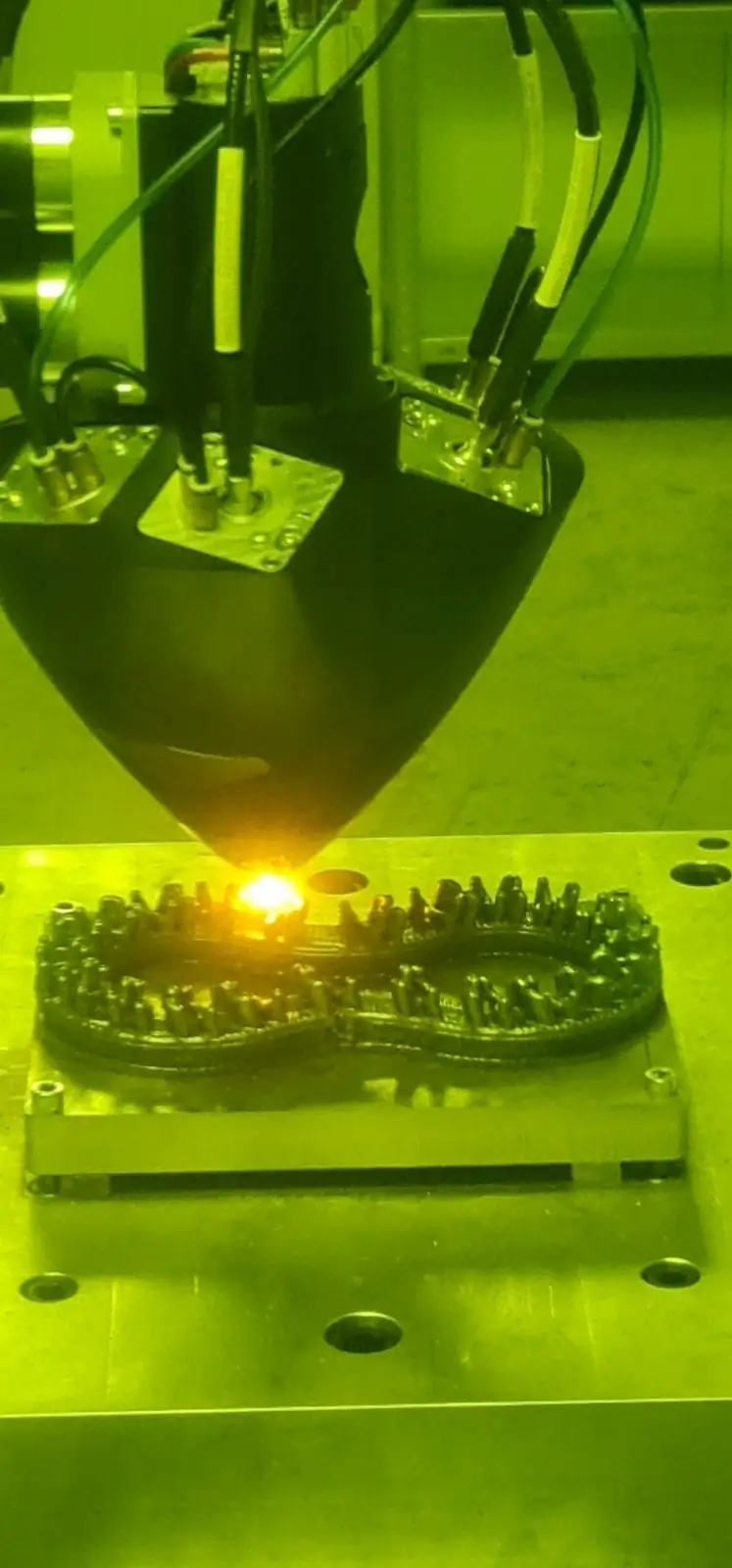

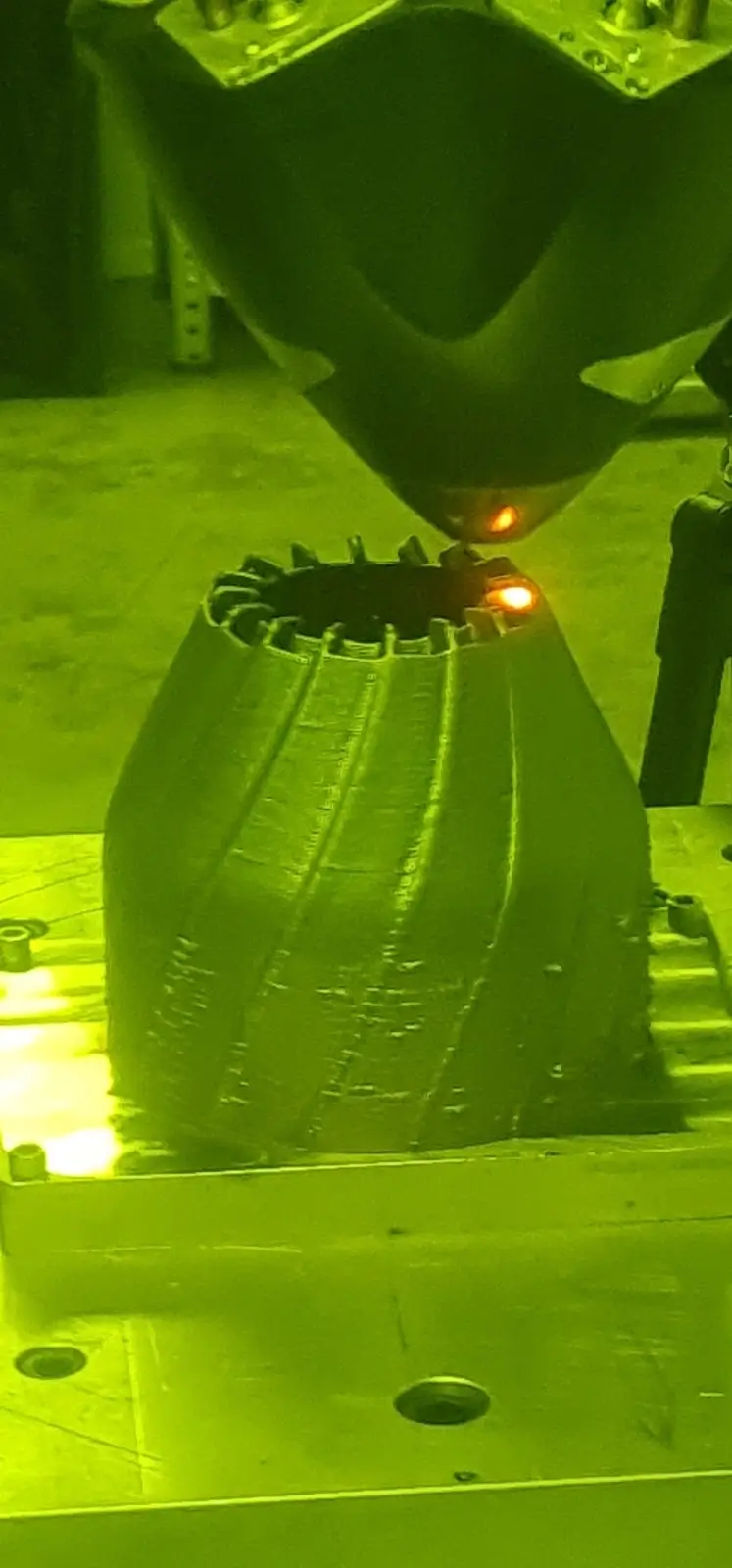

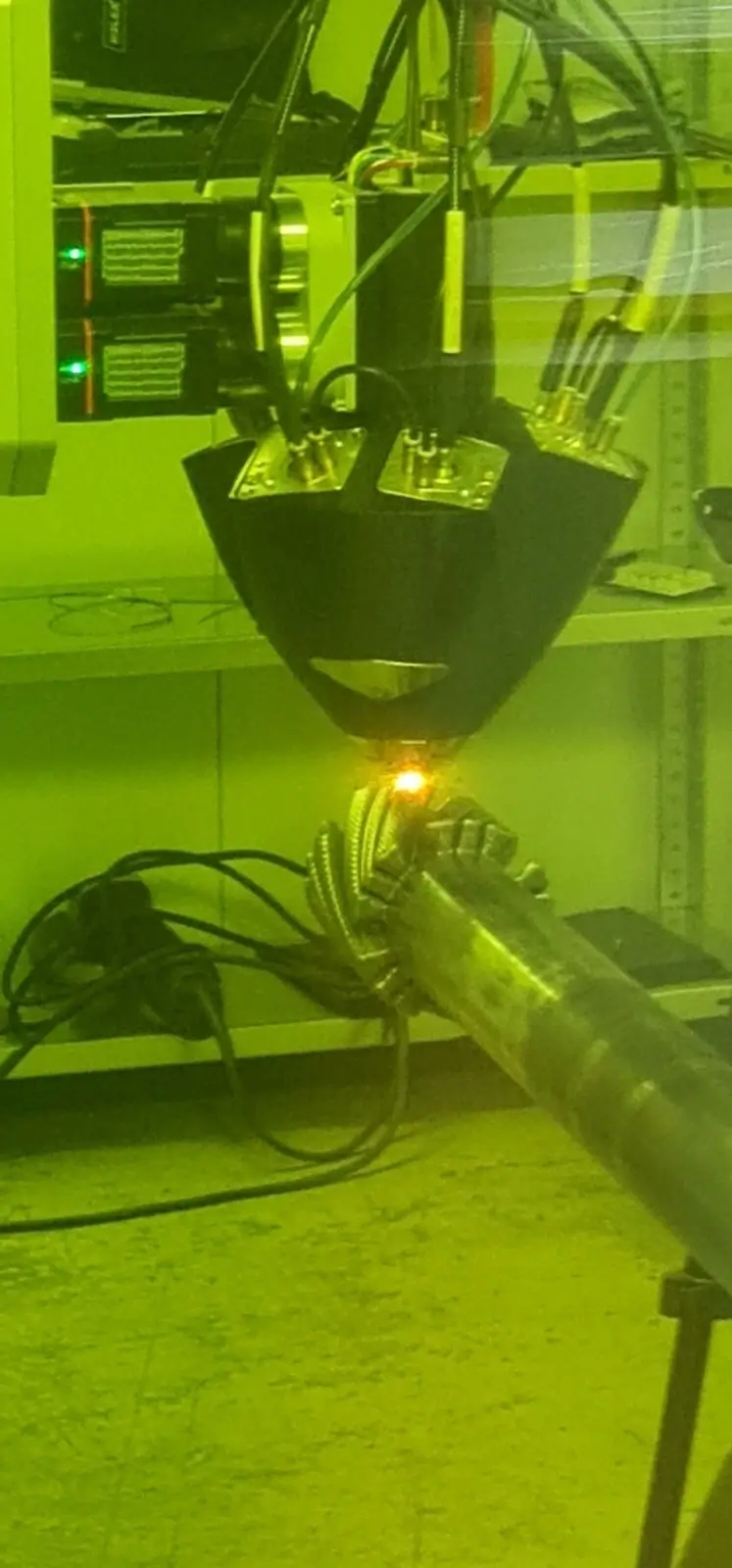

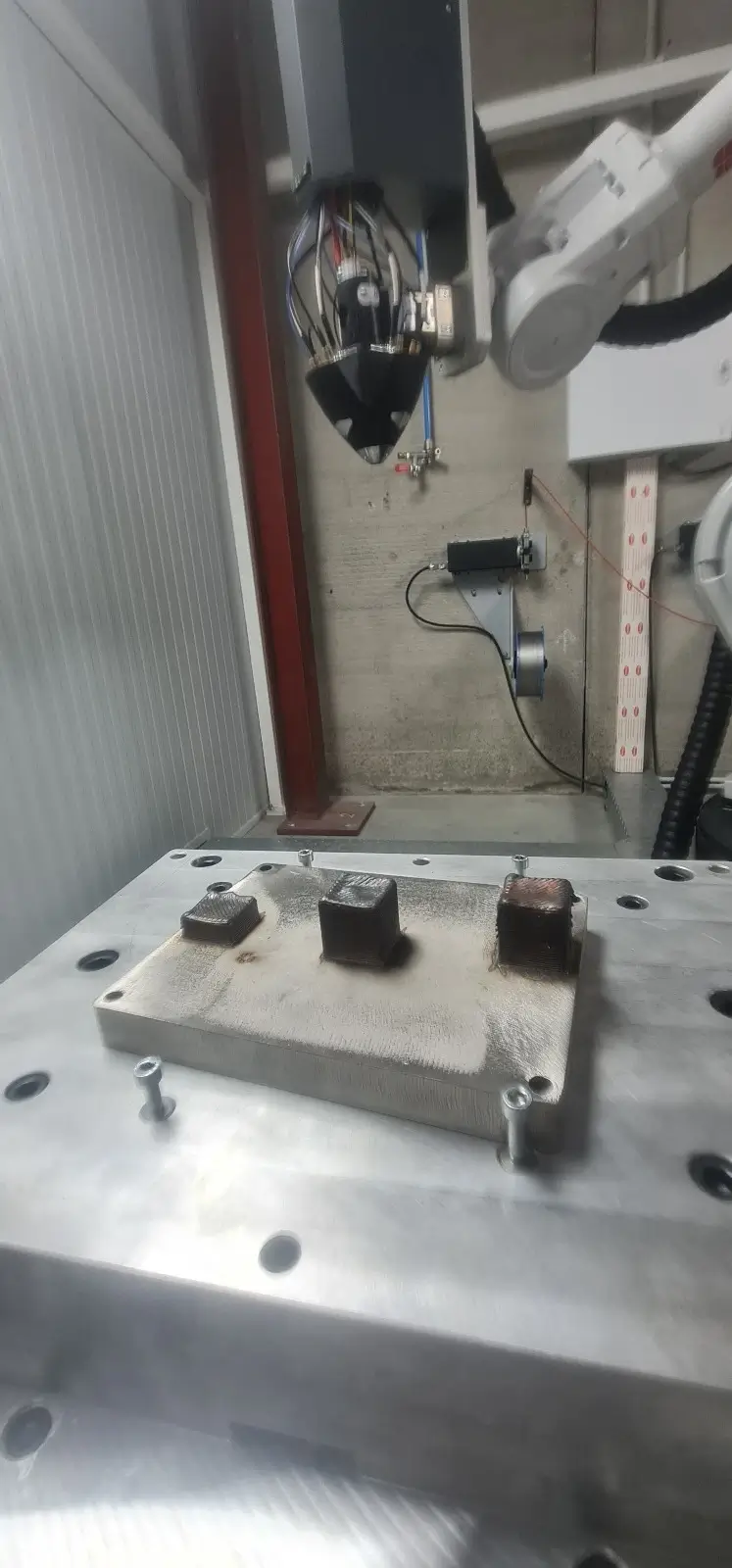

Our new technology: Meltio Engine Robot Integration

Meltio Engine Robot Integration technology transforms industrial robotic arms into advanced 3D printing systems. This machine stands out for its printing capacity without size limits, making it ideal for creating large metal components. It uses a multi-laser approach that increases the speed and accuracy of the process, ensuring high-quality results on every part produced.

The Meltio Engine can handle a variety of metals, including stainless steel, titanium and nickel alloys, providing our customers with unprecedented versatility. In addition, its closed-loop control system ensures efficient and consistent production, minimizing errors and optimizing the quality of the final product. This technology not only enhances our production capabilities, but also opens up new opportunities for our customers to realize more ambitious and customized projects.

Why choose us for your metal 3D printing projects?

From Godiz we want to offer a personalized and quality service in metal 3D printing. Our experience in the sector and the use of cutting-edge technology such as the Meltio Engine allow us to guarantee quality and precision in each project.

Our commitment to innovation and sustainability positions us as a strategic partner in the manufacturing of metal components. By choosing us, you not only get access to state-of-the-art technology, but also a team ready to meet your expectations and contribute to the success of your projects.